About Us

Truck Drive Shaft: The Key Link for Power Transmission

Views : 10

Update time : 2025-07-11 10:54:00

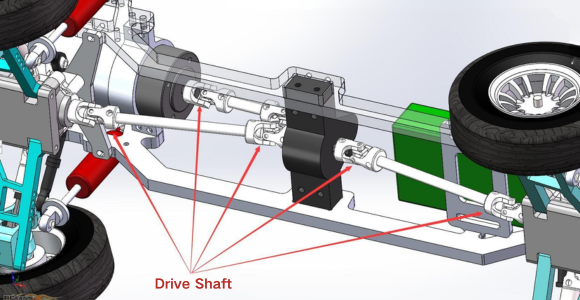

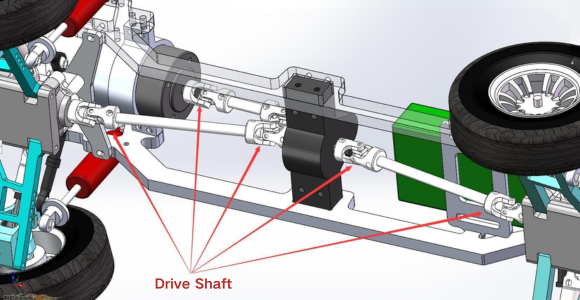

The drive shaft is the core link for power transmission in a truck. Its performance directly affects power transmission efficiency, driving stability, and reliability, ensuring that engine power is accurately transmitted to the driving wheels and enabling the truck to operate normally under various road conditions.

I. Structural Analysis

The drive shaft consists of a shaft tube, a telescopic sleeve, and a universal joint, each with clear functions:

- Shaft Tube: Made of high-strength alloy steel pipe, it bears huge torque and bending moment, providing stable support for power transmission.

- Telescopic Sleeve: Adjusts the distance change between the gearbox and the drive axle. After improvement of the traditional structure, a sealed protective sleeve and oil seal are added to enhance protection and reliability.

- Universal Joint: Like a "joint", it ensures the flexible change of the angle between two shafts to achieve constant velocity transmission, with the cross-shaft type being the most widely used. The sealing sleeve and oil seal on the outside of the drive shaft can prevent dust and rust, extending the service life.

II. Working Principle

After the engine power is shifted and torque-converted by the gearbox, it is transmitted to the drive axle through the drive shaft to drive the wheels. Due to the elasticity of the chassis suspension, the transmission distance and angle of the drive shaft will change dynamically during driving. The telescopic sleeve adjusts the distance, and the universal joint copes with the angle change, ensuring efficient and stable power transmission.

III. Common Faults and Causes

- Looseness and loud noise: A metallic impact sound when starting under heavy load or accelerating is mostly due to excessive wear of the universal joint cross shaft or telescopic sleeve beyond the limit.

- Falling off of connecting bolts: Bending of the drive shaft, unbalanced dynamic balance, loose bolts, or sudden force may cause the bolts to fall off, affecting operation.

- Vehicle shaking: Shaking at a specific speed may be caused by bending or imbalance of the drive shaft, problems with the critical speed design, or damage to the universal joint.

IV. Maintenance Points

- Regular lubrication: Timely apply grease to key parts such as the universal joint and telescopic sleeve to reduce friction and wear.

- Inspection of connecting parts: Regularly tighten connecting bolts, pay attention to the condition of the drive shaft hanger, and replace damaged parts in time.

- Proper driving: Avoid operations such as suddenly lifting the clutch, starting in high gear, and severe overloading. Some vehicles can be equipped with iron chains to prevent the hidden danger of drive shaft breakage.

V. Summary

The drive shaft is the core of power transmission. Although its structure is not complex, its maintenance should be valued. Drivers and maintenance personnel should understand its structure, principle, and fault handling, conduct daily inspections and reasonable operations, ensure the drive shaft is in good working condition, provide guarantee for the safe and efficient operation of the truck, and reduce operating costs and fault risks.

相关新闻

Truck Steering System: Core Guarantee for Control

Truck Steering System: Core Guarantee for Control

Jul 11,2025

This article introduces the truck steering system, which is the core of precise control. It consists of a steering control mechanism, a steering gear, and a steering transmission mechanism, and also includes a power assist system, with types such as mechanical hydraulic, electro-hydraulic, and electric power steering. It also mentions special technologies like rear-wheel steering and intelligent auxiliary steering, as well as maintenance points such as checking steering fluid and component connections, and looks forward to its future trends of electrification and intelligence.

Truck Drive Shaft: The Key Link for Power Transmission

Truck Drive Shaft: The Key Link for Power Transmission

Jul 11,2025

This article briefly introduces the truck drive shaft, which is the core link for power transmission. It is composed of a shaft tube, a telescopic sleeve and a universal joint. It expounds its working principle of transmitting engine power to the drive axle through the gearbox, analyzes common faults such as looseness, bolt falling off and vehicle shaking as well as their causes, and also puts forward maintenance points such as regular lubrication, component inspection and reasonable driving, emphasizing that attention should be paid to its maintenance to ensure the operation of the truck.

Truck Starter: Core of the Starting System

Truck Starter: Core of the Starting System

Jul 11,2025

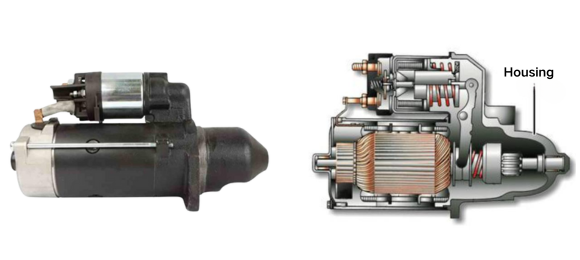

This article focuses on truck starters, introducing them as the core component of the starting system, which can convert the electrical energy of the storage battery into mechanical energy to drive the engine to start. It expounds on its working principle based on DC motors, its structure composed of DC motors, transmission mechanisms and electromagnetic switches, its classification according to the form of DC motors, control devices and the meshing mode of transmission mechanisms, and also lists common faults such as starters not working and idling as well as their solutions. It emphasizes the importance of understanding these for ensuring the operation of trucks.

Guide to Safe Driving of Trucks in Rainy Weather: Wiper Usage and Comprehensive Precautions

Guide to Safe Driving of Trucks in Rainy Weather: Wiper Usage and Comprehensive Precautions

Jul 10,2025

This article focuses on the safe driving of trucks in rainy weather, pointing out that driving in rainy weather is highly risky. It is necessary to control the speed, maintain a safe distance from the vehicle ahead, and check the braking system and tires, etc. It emphasizes the correct use of wipers: check their condition before driving, adjust the speed according to the rainfall, clean them regularly and add appropriate wiper fluid to ensure clear visibility and reduce the risk of accidents.